The two-chamber vortex settlement tank

Usage and Operation

Two-chamber vortex settlement tanks are used to separate and retain suspended particles and grease from wastewater. In the case of suspended particles, gravitational separation of impurities is supported by centrifugal force caused by the vortex movement in the first chamber. The distribution of grease takes place in the second chamber of the settlement tank as a result of gravitational flotation. Two-chamber vortex settlement tanks are used mainly to pretreat sewage from urban watersheds and roads where there is a low risk of high levels of pollution from petroleum derivatives.

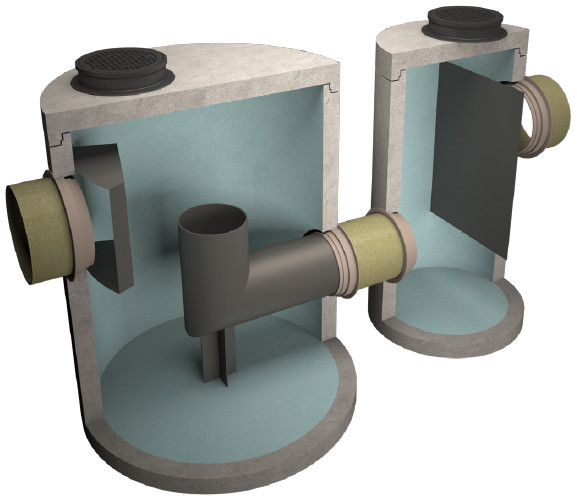

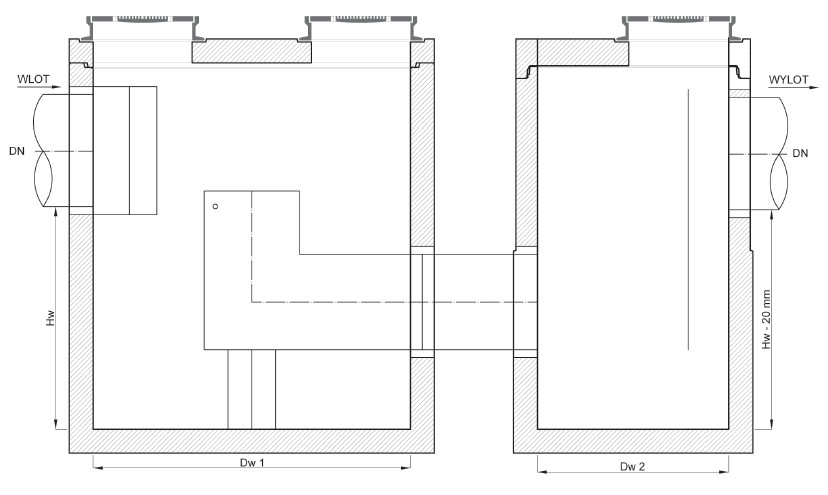

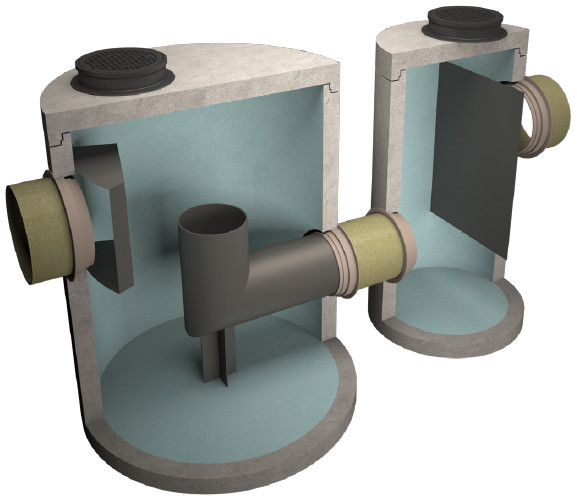

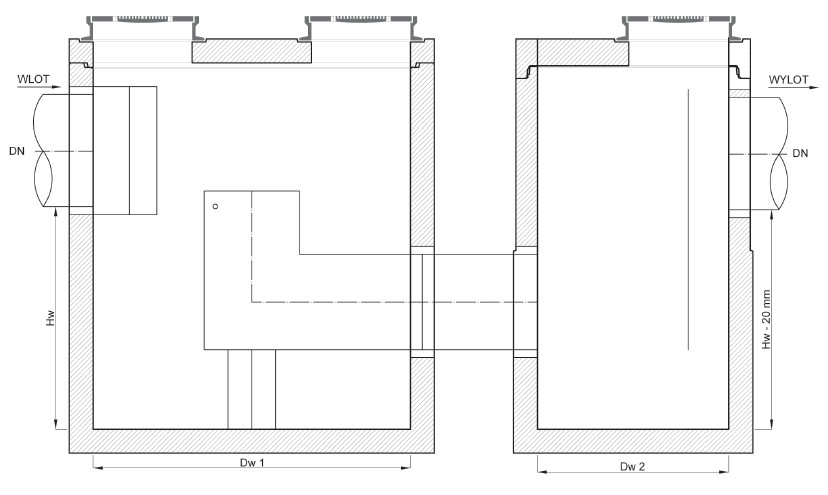

Construction

Vessel tanks for two-chamber vortex tanks are made of precast concrete, reinforced concrete or plastic. The inlet is inserted tangentially to the wall of the tank or is equipped with a directional deflector forcing rotation. In the central part of the first tank there is a drain outlet for sludge free wastewater to enter the second chamber. The second tank acts as a gravity separator and is equipped with a compartment for trapping light pollution. For the largest devices where the frames are delivered in elements (B in the type of device), the equipment is assembled on construction site. Optionally, two-chamber vortex settlers can be equipped in residue and grease level sensors.

|

|

The two-chamber vortex settlement tank NIXOR-NOWD

Settling tanks NIXOR-NOWD

| Typ urządzenia |

Wielkość nominalna |

Przepustowość |

Średnica wew. zbiornika 1 |

Średnica wew. zbiornika 2 |

Wysokość dopływu |

Zagłebienie minimalne* |

Średnica rur |

Pojemność części osadowej |

Pojemność

magazynowania

oleju |

Karta katalogowa |

Deklaracja zgodności |

| NS |

Qmax |

Dw1 |

Dw2 |

Hw |

Z |

DN |

Vos |

Vol |

| dm3/s |

mm |

mm |

m |

m |

mm |

dm3 |

dm3 |

| NOWD 3/30 |

3 |

30 |

1000 |

1000 |

0,75 |

0,90 |

≤400 |

580 |

490 |

|

|

| NOWD 6/60 |

6 |

60 |

1000 |

1000 |

0,75 |

0,90 |

≤400 |

580 |

490 |

|

|

| NOWD 10/100 |

10 |

100 |

1200 |

1000 |

1,56 |

1,04 |

≤500 |

1750 |

1100 |

|

|

| NOWD 15/150 |

15 |

150 |

1200 |

1000 |

1,56 |

1,04 |

≤500 |

1750 |

1100 |

|

|

| NOWD 20/200 |

20 |

200 |

1200 |

1000 |

1,56 |

1,04 |

≤500 |

1750 |

1100 |

|

|

| NOWD 25/250 B |

25 |

250 |

1200 |

1200 |

1,95 |

0,90 |

≤500 |

2190 |

1930 |

|

|

| NOWD 30/300 |

30 |

300 |

1500 |

1200 |

1,49 |

1,16 |

≤600 |

2610 |

1380 |

|

|

| NOWD 35/350 B |

35 |

350 |

1500 |

1200 |

1,74 |

1,16 |

≤600 |

3050 |

1680 |

|

|

| NOWD 40/400 |

40 |

400 |

2000 |

1200 |

1,40 |

1,20 |

≤700 |

4340 |

1280 |

|

|

| NOWD 50/500 |

50 |

500 |

2000 |

1200 |

1,40 |

1,20 |

≤700 |

4340 |

1280 |

|

|

| NOWD 60/600 B |

60 |

600 |

2000 |

1500 |

1,84 |

1,31 |

≤800 |

5720 |

2470 |

|

|

| NOWD 65/650 B |

65 |

650 |

2000 |

1500 |

1,84 |

1,31 |

≤800 |

5720 |

2470 |

|

|

| NOWD 70/700 |

70 |

700 |

2500 |

1500 |

1,34 |

1,31 |

≤800 |

6490 |

1720 |

|

|

| NOWD 75/750 |

75 |

750 |

2500 |

1500 |

1,34 |

1,31 |

≤800 |

6490 |

1720 |

|

|

| NOWD 80/800 B |

80 |

800 |

2500 |

1500 |

1,79 |

1,36 |

≤900 |

8700 |

2380 |

|

|

| NOWD 90/900 B |

90 |

900 |

2500 |

1500 |

1,79 |

1,36 |

≤900 |

8700 |

2380 |

|

|

| NOWD 100/1000 B |

100 |

1000 |

2500 |

1500 |

1,79 |

1,36 |

≤900 |

8700 |

2380 |

|

|

| NOWD 110/1100 B |

110 |

1100 |

3000 |

2000 |

1,72 |

1,43 |

≤1000 |

12020 |

2710 |

|

|

| NOWD 120/1200 B |

120 |

1200 |

3000 |

2000 |

1,72 |

1,43 |

≤1000 |

12020 |

2710 |

|

|

| NOWD 125/1250 B |

125 |

1250 |

3000 |

2000 |

1,72 |

1,43 |

≤1000 |

12020 |

2710 |

|

|

| NOWD 130/1300 B |

130 |

1300 |

3000 |

2000 |

1,72 |

1,43 |

≤1000 |

12020 |

2710 |

|

|

| NOWD 140/1400 B |

140 |

1400 |

3000 |

2000 |

1,99 |

1,66 |

≤1200 |

13930 |

4620 |

|

|

| NOWD 150/1500 B |

150 |

1500 |

3000 |

2000 |

1,99 |

1,66 |

≤1200 |

13930 |

4620 |

|

|

| NOWD 160/1600 B |

160 |

1600 |

3000 |

2000 |

1,99 |

1,66 |

≤1200 |

13930 |

4620 |

|

|

| NOWD 180/1800 B |

180 |

1800 |

4600 |

2500 |

3,42 |

2,53 |

≤1400 |

54850 |

15290 |

|

|

| NOWD 300/3000 B |

300 |

3000 |

4600 |

2500 |

3,42 |

2,53 |

≤1400 |

54850 |

15290 |

|

|

| NOWD 320/3200 B |

320 |

3200 |

5000 |

3000 |

3,42 |

2,53 |

≤1400 |

67650 |

15290 |

|

|

| NOWD 360/3600 B |

360 |

3600 |

5000 |

3000 |

3,42 |

2,53 |

≤1400 |

67650 |

15290 |

|

|

| NOWD 380/3800 B |

380 |

3800 |

5600 |

3000 |

3,42 |

2,53 |

≤1600 |

88440 |

15290 |

|

|

| NOWD 480/4800 B |

480 |

4800 |

5600 |

3000 |

3,42 |

2,53 |

≤1600 |

88400 |

15290 |

|

|

| NOWD 500/5000 B |

500 |

5000 |

6000 |

3000 |

3,42 |

2,53 |

≤1600 |

103950 |

15290 |

|

|

| NOWD 560/5600 B |

560 |

5600 |

6000 |

3000 |

3,42 |

2,53 |

≤1600 |

103950 |

15290 |

|

|

* Z - designated for the maximum pipe diameter for a given device; individual solutions will be used in the case of depth less than the minimum

B - devices delivered in elements for assembly on the construction site by the ordering party.

NIXOR reserves the right to make design changes without prior notification.

In individual solutions, it is possible to increase the grease capacity of the settling tank.

Aby zobaczyć pełną specyfikację produktu proszę otworzyć stronę na komputerze.